If you have any question, please contact us

If you have any question, please contact us

TiC powder introduced:

Titanium carbide powder,Chemical formula TiC,Molecular weight 59.91,Carbon content 20.05%,Density 4.93g/cm3, Melting point:3160ºC,Boiling point 4300ºC.Titanium carbide is off-white powder with cubic system structure of NaCl type.The carbide is mainly used in preparation of cermet,heat-resistant material and cemented carbide due to its high melting point ,hardness and chemical stability. The wear-resistance,corrosion resistantce and resistance to oxidation of hard alloy can be improved clearly when TiC(6~30%)is mixed in WC-Co cemented carbide and form TiC-WC solid solution with WC.It is more suitable to process steel products.Also we can produce cemented carbide without tungsten using Ni-Co alloy to enhance the cutting speed and precision and smoothness of processed component.

TiC Titanium Carbide Powder,density: 4.93g/cm3, melting point: 3140°C,boiling point:4300℃,English name: titanium carbide powder, CAS NO.,: 12070-08-5, Molecular formula:TiC,grey black powder with cubic system NaCI structure.As high melting point,high hardness,good chemical stability.

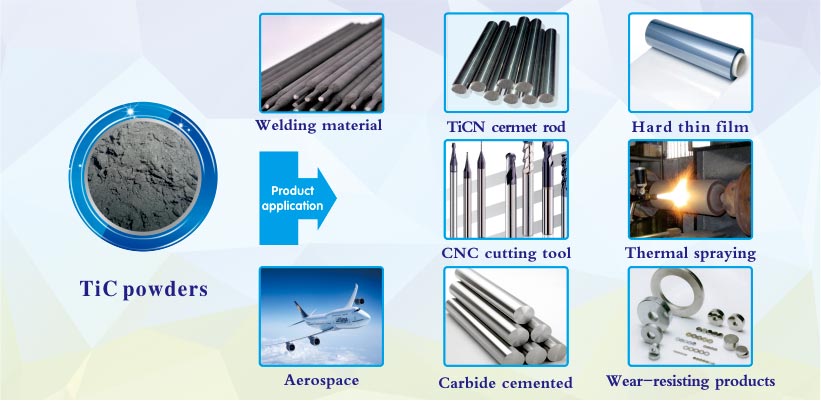

The carbide is mainly used in manufacturing of cermet,heat-resistant alloy and cemented carbide due to its high melting point,high hardness and good chemical stability.Titanium carbide can form a binary,ternary,quaternary compound solid solution with tungsten carbide, titanium carbide, niobium carbide, chromium nitride,and titanium nitride,applies in the spray coating material,the welding material,the flinty membranous material,the military aviation material,the hard alloy and the cermet.

Changsha Langfeng metallic material Co.,Ltd titanium carbide products advantages:

Using high purity titanium oxide and high purity carbon black as raw materials,to ensure the purity of titanium carbide powder.

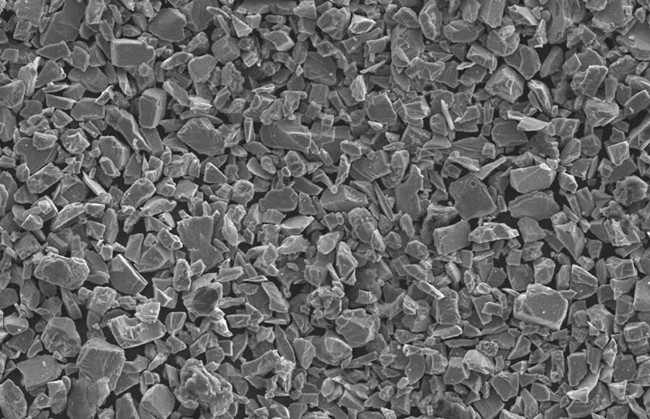

The company's original additive application technology make the powder grain densification,carbonization sintering uniform and uniform size.

Unique carbonization sintering technology to ensure a low oxygen content,low free carbon, product quality and stability.

Application:

Titanium carbide powder be applied in high temperature thermal spraying materials, welding materials, rigid film materials, military aviation materials, cemented carbide and metal ceramics.

Adding 6-30% titanium carbide powder into WC-Co serious tungsten carbide products,could form TiC-WC solid solution,then enhance the alloy’s performance in glowing red,high hardness,oxidation resistance,corrosion resistance and so on,more suitable for processing steel than WC-Co tungsten carbide.Widely application in tungsten carbide cutting tools products.

Also we can produce cemented carbide without tungsten using Ni-Co alloy to enhance the cutting speed and precision and smoothness of processed component.

Chemical Characteristics:

|

Medium/Fine Grain Size |

|||||||||

|

Grade |

Chemical Contents(%) |

particle size (um) |

|||||||

|

Total Carbon (T.C.) |

Free Carbon |

Impurity Contents(<=%) |

|||||||

|

Si |

Al |

O |

N |

Na |

Ca |

||||

|

TiC-1 |

>19.0 |

<0.40 |

0.05 |

0.01 |

1.0 |

0.5 |

0.01 |

0.02 |

0.8-1.5 |

|

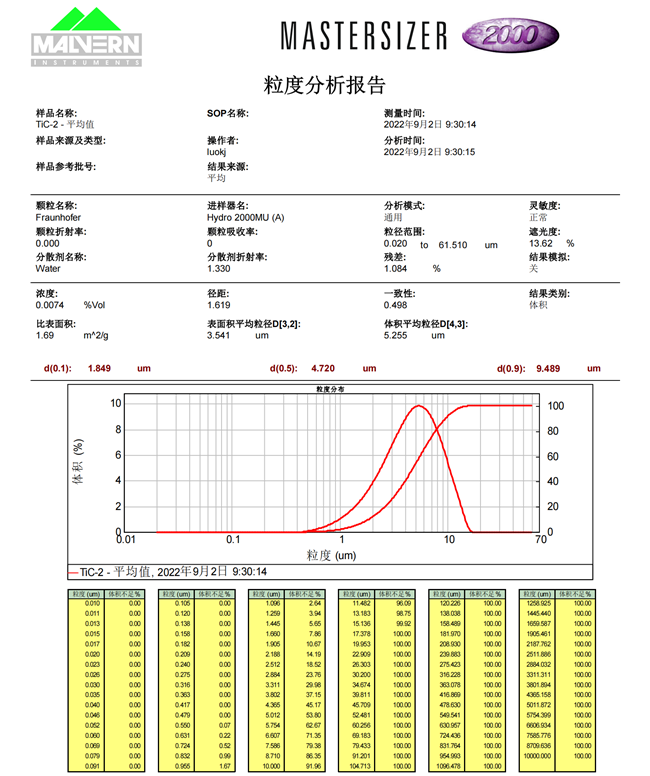

TiC-2 |

>19.0 |

<0.40 |

0.05 |

0.01 |

0.5 |

0.6 |

0.01 |

0.02 |

3-10 |

|

TiC-3 |

>19.0 |

<0.35 |

0.05 |

0.01 |

0.4 |

0.5 |

0.01 |

0.02 |

75-150 |

|

TiC-4 |

>15 |

<0.3 |

0.05 |

0.01 |

0.3 |

0.4 |

0.01 |

0.02 |

1000-4000 |

Note: We can make the different particle size and chemical composition according to customize.